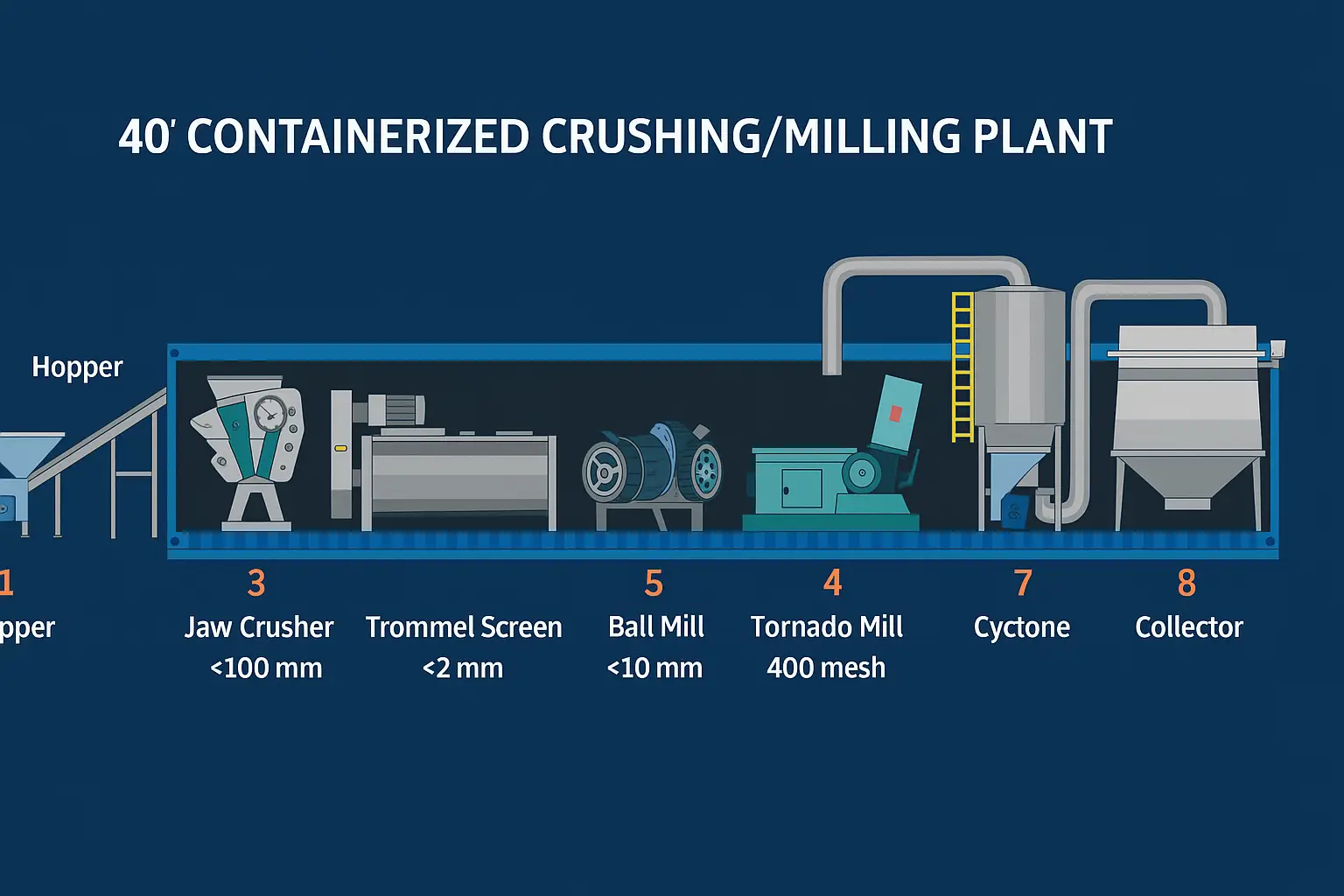

The 40-foot containerized crushing and milling plant is a fully enclosed, modular system that enables efficient on-site material reduction — from raw ore to ultrafine powder. Designed for plug-and-play deployment, this unit is ideal for remote locations, pilot projects, and modular production setups.

⚙️ System Flow & Components

- Hopper & Belt Conveyor

Material is first fed into the hopper, which transfers it via belt conveyor into the processing line with smooth, controlled flow. - Jaw Crusher (<100 mm)

The jaw crusher performs primary size reduction, crushing large rocks and ore to under 100 mm. - Hammer Crusher (>1/2″)

The crushed material then enters the hammer crusher, which reduces it further to less than 1/2 inch — an ideal size for final pulverization. - Feeder

A precision feeder ensures consistent delivery of material into the ultra-fine pulverizing system, enhancing energy efficiency and throughput. - Tornado Pulverizer (400 mesh)

The Tornado mill finely grinds the feed material to 400 mesh (approx. 38 microns), suitable for direct leaching, gravity separation, or advanced beneficiation. - Cyclone Separator

The cyclone separates fine particles from air, directing powder to collection and ensuring minimal loss and system efficiency. - Impulse Dust Collector

All remaining fine dust is captured by the impulse dust collector, keeping the system clean and fully compliant with environmental standards.

✅ Key Benefits

- Completely Containerized: Ships globally as a standard 40’ unit for easy deployment.

- No Ball Mill Needed: Uses hammer crusher + high-speed pulverizer for direct fine grinding.

- Compact & Efficient: Full process in a small footprint with minimal power requirements.

- Clean Processing: Built-in cyclone and dust collector ensure safe, dust-free operation.

- Field-Ready: No concrete foundation required; install, connect, and start.

🛠️ Suitable For

- Precious metal ores (Au, Ag)

- REE, PGM ores

- Tailings and slag reprocessing

- Ceramic and industrial mineral powder production

- Pilot plants and mobile operations

Conclusion

The containerized crushing and milling plant (no ball mill) offers a high-efficiency, low-maintenance solution for portable fine grinding. Whether for gold, rare earths, or industrial feedstock, this unit delivers power, precision, and portability in one complete package.