Transform

Your Business

With AI-Driven Mineral Processing

AI Automation

Boost recovery rates and reduce waste with intelligent process control.

Machine Learning

Optimize ore analysis, separation, and throughput using real-time data insights.

Connect With Us

Trusted Solutions by Avimetal Inc.

Avimetal Inc. pioneers advanced mineral processing technologies, combining AI, automation, and eco-friendly systems to revolutionize how critical minerals are recovered and refined across industries.

Powered

Innovation in Mineral Processing

Turning Ore into Opportunity with AI

Avimetal Inc. integrates AI, automation, and sustainable technologies to unlock the full value of mineral resources.

Empowering the Future of Mineral Processing

At Avimetal Inc., we harness the power of AI, automation, and eco-friendly technologies to revolutionize mineral recovery. Our intelligent systems optimize extraction, reduce waste, and improve decision-making across mining and refining operations.

What We Do

- AI-Driven Automation – Streamline mineral processing with precision control and real-time adjustments.

- Predictive Analytics – Use AI insights to enhance yield, forecast ore quality, and improve operational planning.

Our Mission

To revolutionize the global mineral industry with smart, sustainable processing technologies that boost efficiency, recovery, and environmental responsibility.

Who We Are

Avimetal Inc. is a team of engineers, AI specialists, and metallurgical innovators dedicated to transforming mining with intelligent, green technologies.

Our Breakthrough Mineral Processing Technologies

At Avimetal Inc., we offer a suite of cutting-edge solutions—dry concentration, plasma refining, and AI-enhanced electrowinning—designed to transform the way minerals are recovered, refined, and optimized for a sustainable future.

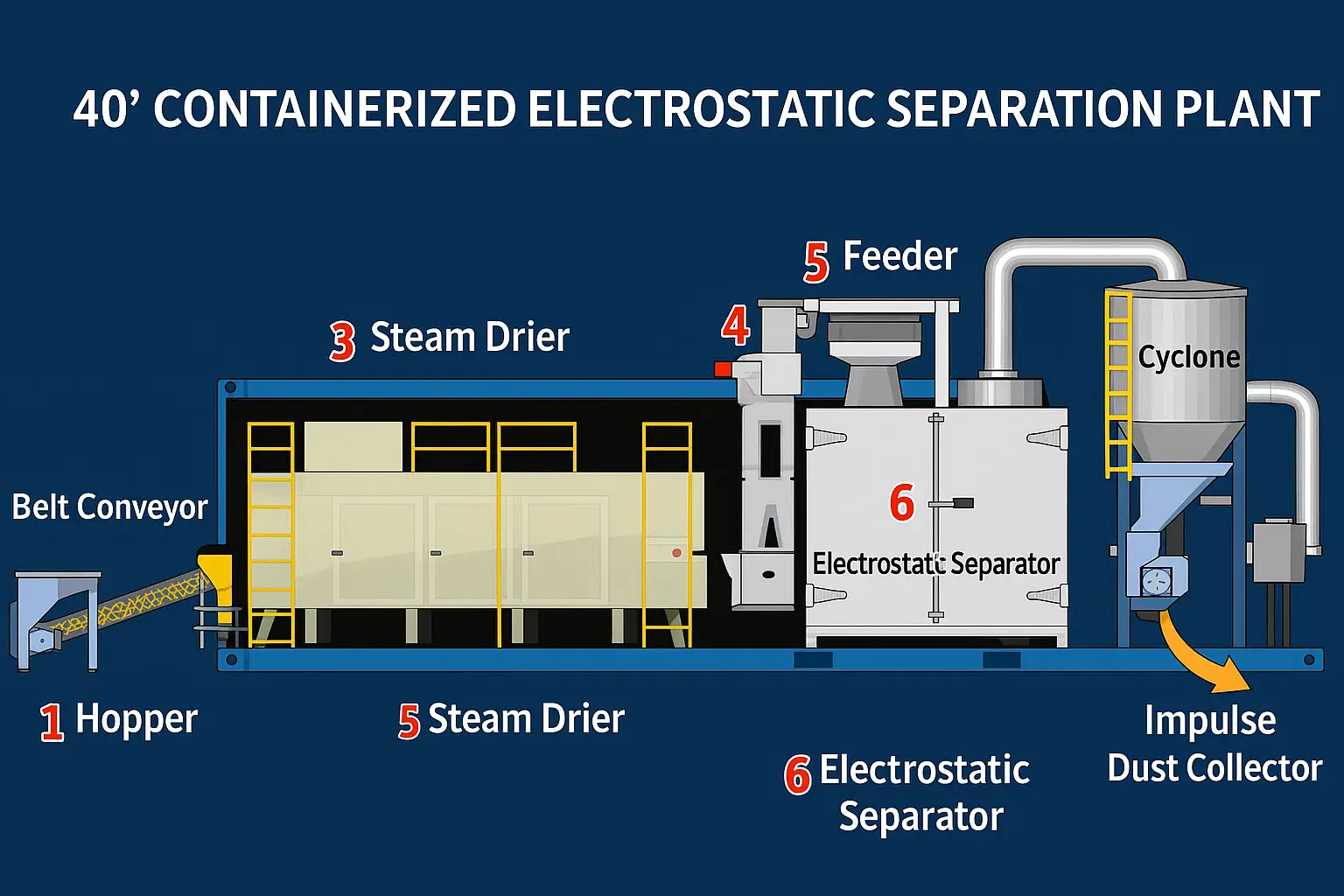

Electrostatic Dry Washer

Efficiently separates conductive and non-conductive mineral particles without water—ideal for remote or arid mining sites.

Hybrid Plasma System

Advanced plasma-based technology that breaks down complex ores, recovers metals with minimal emissions, and supports eco-friendly refining.

Cyclone Electrowinning Cell

Compact, high-throughput electrowinning cell that increases purity and recovery speed using controlled vortex flow for efficient metal deposition.

Why Choose OpticAI?

At Avimetal Inc., we integrate cutting-edge AI, automation, and sustainable systems to revolutionize mineral recovery and refining. Our technologies are designed to enhance efficiency, reduce waste, and enable scalable, eco-friendly operations across the mining industry.

Expertise in Smart Mineral Engineering

Our team of metallurgists, engineers, and AI experts brings decades of experience in ore concentration, refining, and advanced mineral separation.

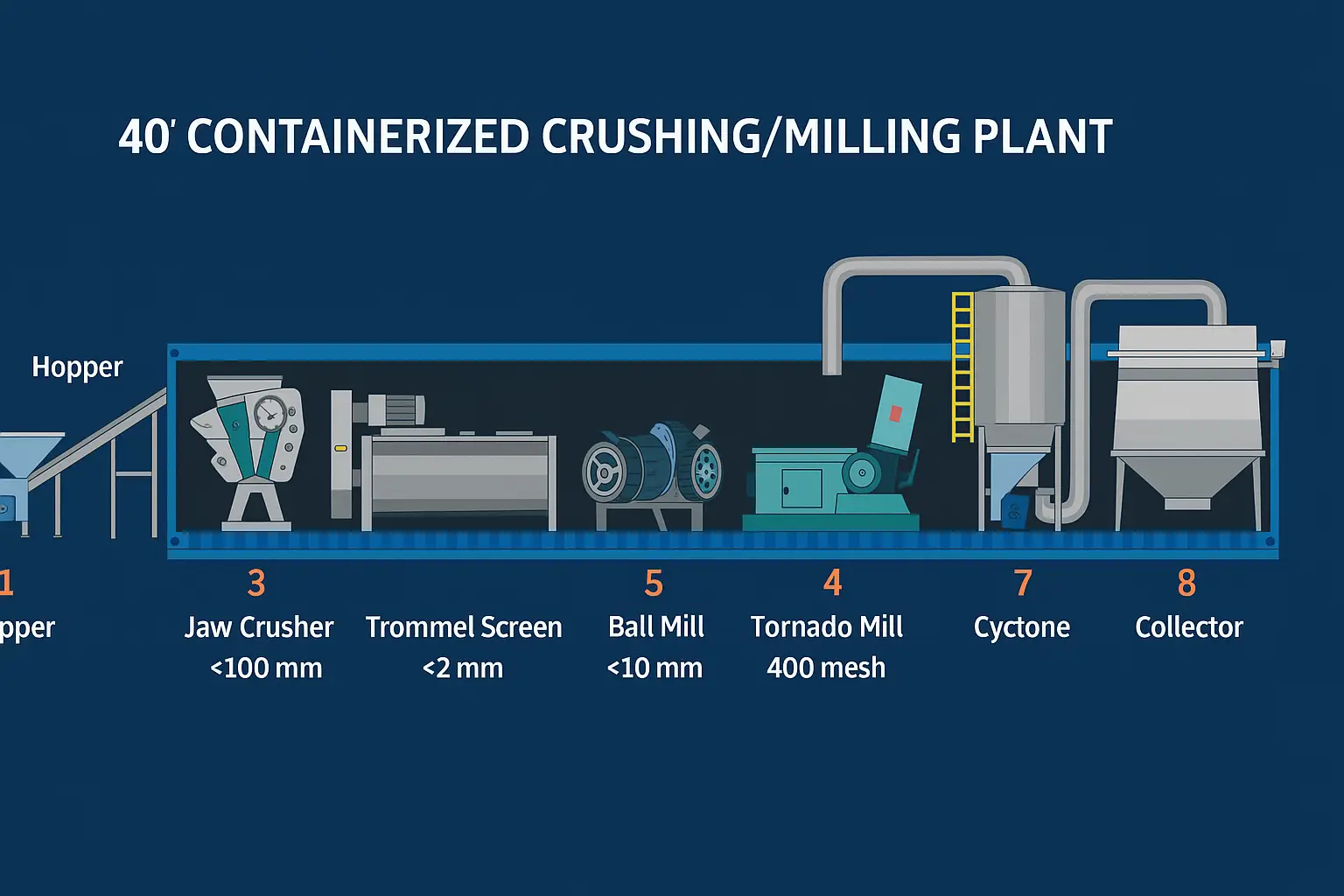

Scalable & Future-Ready Solutions

Our modular systems adapt to any site size—from mobile setups to high-capacity plants—ensuring long-term growth and flexibility..

Proven Results & Innovation

From pilot systems to full-scale operations, Avimetal technologies have consistently improved metal yields while lowering environmental impact.

End-to-End Support & Integration

We collaborate closely with clients to deliver tailored processing systems, on-site training, and ongoing technical support to maximize ROI.

What Our Clients Say

At Avimetal Inc., we pride ourselves on delivering breakthrough mineral processing technologies that drive efficiency, sustainability, and profitability. Here’s what our partners have to say about their experience with us:

Driving Innovation in Mineral Processing

At Avimetal Inc., we are committed to delivering advanced, eco-friendly mineral processing systems that empower clients to reduce costs, improve recovery, and minimize environmental impact. Our dedication to innovation has led to industry-defining technologies used across the globe.

Latest Insights & Technology Breakthroughs

Stay up to date with Avimetal’s innovations, field applications, and next-gen developments in mineral recovery, refining, and sustainability.

Ready to Transform Your Mineral Processing Operation?

Empower your business with advanced mineral recovery technologies that deliver higher efficiency, lower costs, and greater sustainability. Whether you need dry separation, hybrid plasma refining, or intelligent electrowinning, Avimetal Inc. is your trusted partner in innovation.