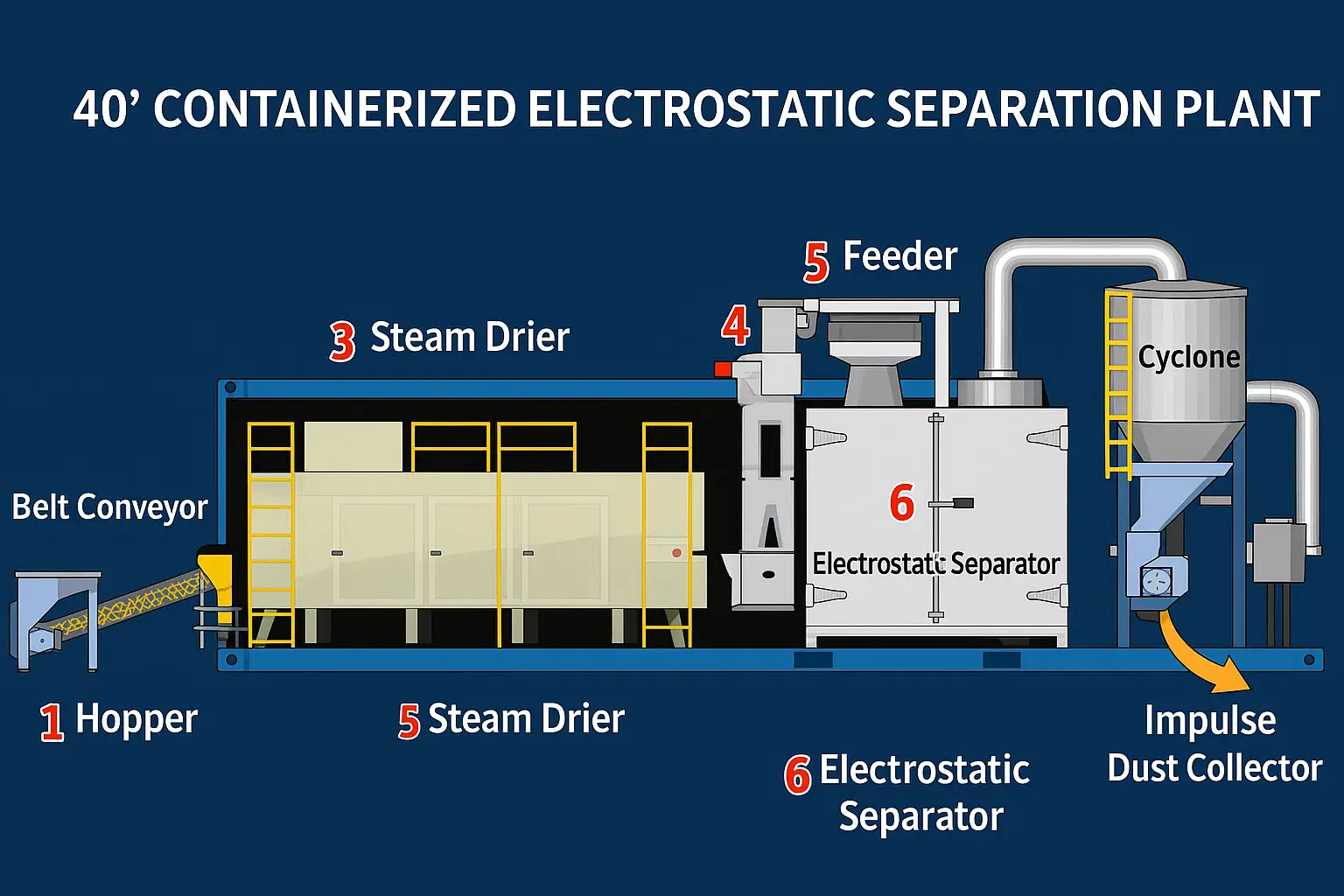

The 40-foot containerized electrostatic separation plant is a cutting-edge, modular solution for efficient mineral recovery and industrial dust control. Designed for mobility and fast deployment, this compact plant integrates advanced processing technologies into a single, container-sized system ideal for remote mining operations, pilot testing, or small-to-mid scale production.

Key Components & Process Flow

- Hopper & Belt Conveyor

Raw material is first fed into the hopper, where it is evenly distributed onto a belt conveyor. This conveyor transports the material into the processing container, ensuring continuous and controlled input. - Steam Drier

The material passes through a steam drying system that rapidly reduces moisture content. Efficient drying is critical for maximizing the effectiveness of electrostatic separation, as dry particles respond better to electric charges. - Feeder & Pre-separator

Dried material is funneled into a vibratory feeder that ensures a consistent and uniform flow into the separation chamber. This stage may include a screening mechanism to remove oversize particles. - Electrostatic Separator

At the heart of the system is the Electrostatic Separator, a high-efficiency device that uses a strong electrostatic field to separate conductive from non-conductive particles. This is ideal for recovering valuable metals from slag, tailings, and mineral ores, and for processing e-waste or industrial residues. - Cyclone & Impulse Dust Collector

A robust cyclone system separates heavy particles from light airborne dust. The remaining fine particulates are captured by an impulse dust collector, ensuring the plant meets environmental standards and minimizes airborne pollutants.

Advantages of the Containerized Design

- Mobility: Easily transportable by truck or container ship to any site.

- Plug-and-Play Setup: Fast installation with minimal civil work.

- Compact Footprint: Integrates multiple process units into a single container.

- Energy Efficient: Low power consumption due to high-efficiency components.

- Eco-Friendly: Captures and controls dust emissions, improving worker safety and air quality.

Applications

- Processing precious and base metal slags

- E-waste recovery

- Mineral concentration from tailings

- Separation of industrial residues

- Pilot testing for new mining projects

Conclusion

The 40’ containerized electrostatic separation plant offers a powerful, scalable, and mobile solution for modern mineral and waste processing. It enables operators to unlock value from challenging feedstocks with minimal environmental impact, making it a game-changing innovation in the field of sustainable resource recovery.