Electrostatic Separation for Ore Concentration: Extracting Minerals with Electric Charges

Ore concentration through electrostatic separation is a sophisticated process that leverages electrical charges to effectively separate minerals within an ore. This technique is particularly valuable for isolating minerals like cassiterite, rutile, zircon, and ilmenite from their respective ores.

The process initiates with the ore being finely crushed and ground into a powder. Subsequently, the powdered ore is conveyed onto a moving belt, passing over a roller that carries a static electrical charge. This roller imparts a positive charge to the mineral particles targeted for separation. As a result, these charged particles are irresistibly drawn towards a negatively charged plate or drum positioned on the opposite side of the moving belt.

The minerals, attracted to the negatively charged plate, undergo separation from the remainder of the uncharged ore. The isolated minerals are then collected for further processing.

Electrostatic separation finds extensive application in mineral processing plants, where it serves to segregate valuable minerals from undesired gangue minerals or other unwanted materials. It proves to be an efficient and cost-effective method for concentrating minerals, especially those exhibiting varying electrical conductivity properties.

Nevertheless, it is crucial to acknowledge that electrostatic separation may not be universally effective for all mineral types and ores. Depending on the specific ore composition, complementary concentration techniques might be required in conjunction with electrostatic separation.

An electrostatic separator is a device designed to separate particles by mass using a low-energy charged beam. It operates based on the principle of corona discharge, with two plates positioned closely and subjected to high voltage. This high voltage induces the separation of ionized particles. By employing electrostatic charges, this process effectively separates crushed particles of material, enabling the extraction of valuable substances from ore. Typically, electrostatic charges are utilized to attract or repel materials with different charges.

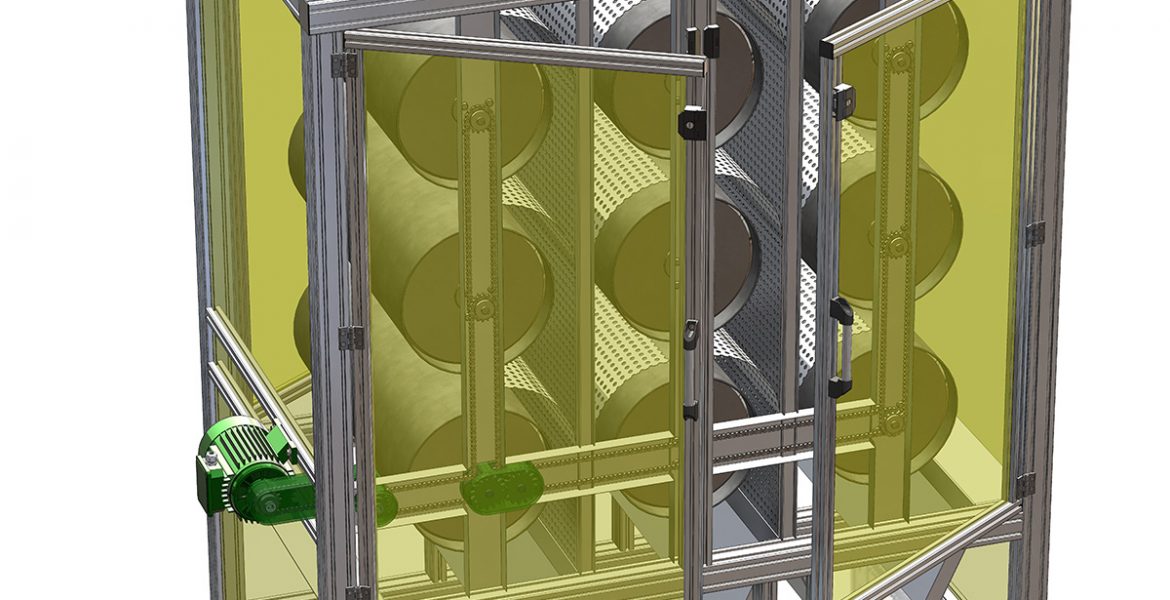

Our electrostatic separators boast a unique combination of roller and belt types, setting them apart as superior solutions in the market. The system features eight pairs of vertically positioned plates and one pair of rollers, offering several advantages over competitors.

One of the key benefits of this system is its compact size, making it highly space-efficient for your operations. Additionally, we take pride in offering these separators at a low sales price, ensuring that you receive exceptional value for your investment.

With the capability of separating micron-sized particles, our electrostatic separators demonstrate exceptional precision and efficiency in their performance. Moreover, they exhibit a remarkable large production capacity, allowing you to handle substantial volumes of material with ease.

Notably, these separators are designed to operate using low power, minimizing energy consumption and contributing to cost savings in the long run.

Choose our cost-effective electrostatic separators for a reliable, high-performance solution that meets your separation needs while delivering affordability and sustainability.